- 812-933-5421

- 1116 IN-46 W, BATESVILLE, IN 47006

- "IT'S HOW WE OPERATE!"

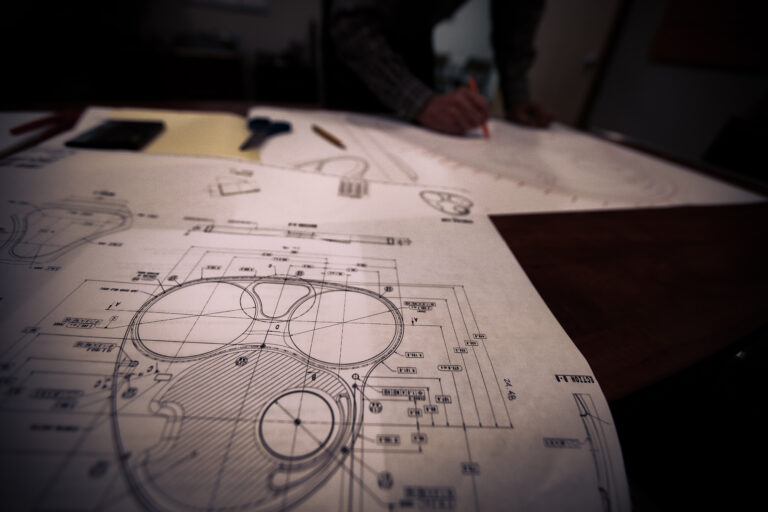

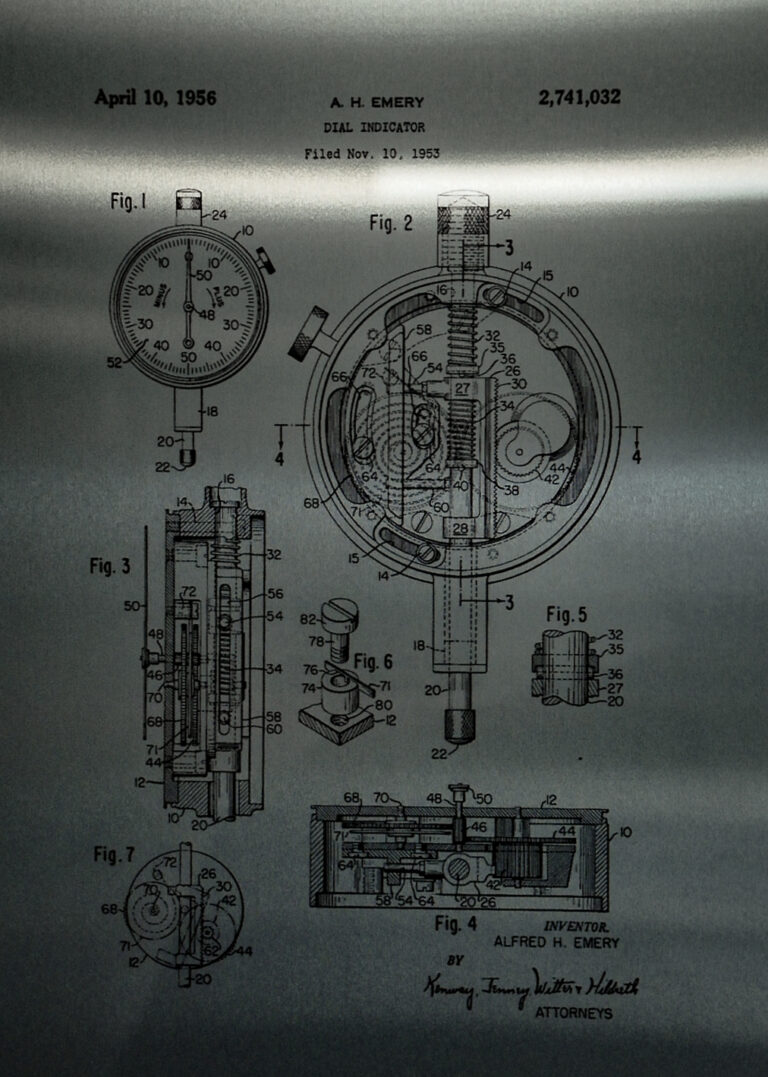

Integrity Tool, Inc., located in Batesville Indiana designed and built their first gage in November of 2002. Since then thousands of gages have been designed and built ranging from simple hand held Go/No-Go attribute gages to complex fixtures incorporating PLC control, digital probes, and data collection. Though inspection fixtures have been our focus, we also have experience with all other types of fixtures and tooling.

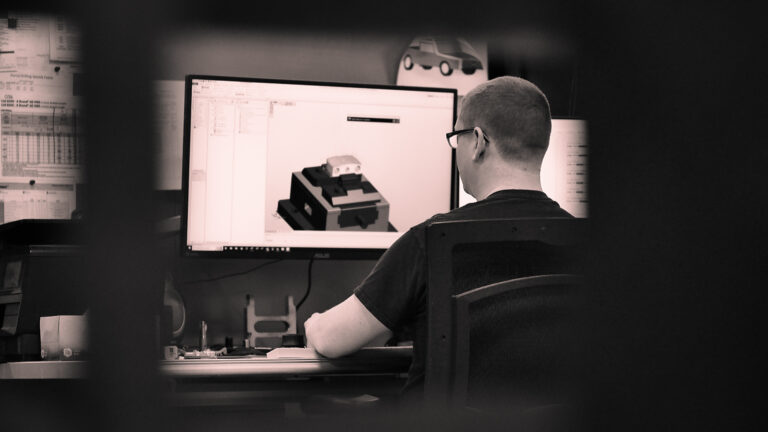

Our ISO-9001 accredited shop is fully furnished to handle the most challenging projects. Starting in design with SolidWorks CAD, continuing through the shop with 3 and 5 axis machining capability, WEDM, Surface Grinding, Jig Grinding and OD grinding, Integrity Tool has the resources to get your projects completed in a timely and efficient manner.

Benchmark Metrology, Inc is a wholly owned subsidiary of Integrity Tool providing the certification required to put our gages directly onto your manufacturing floor. Benchmark Metrology maintains the rigorous requirements of the ISO-17025 lab accreditation to provide you with the confidence that the gages and inspection fixtures provided meet the design specifications you require.

Integrity is not just our name, it’s who we are. It’s our primary core value. It’s the word that best describes how we strive to do business. Our definition is, it’s doing the right thing every time, all the time. At the end of the day, we want our customers to trust us and the products that we’re providing to them. We appreciate the decisions they make using our gages and fixtures. We don’t take lightly the confidence that they place in us.

Whether you’re looking for a new source for your precision gaging needs or if you’re looking for a new team to share your talents with, let Integrity Tool show you the value that we bring to the marketplace.