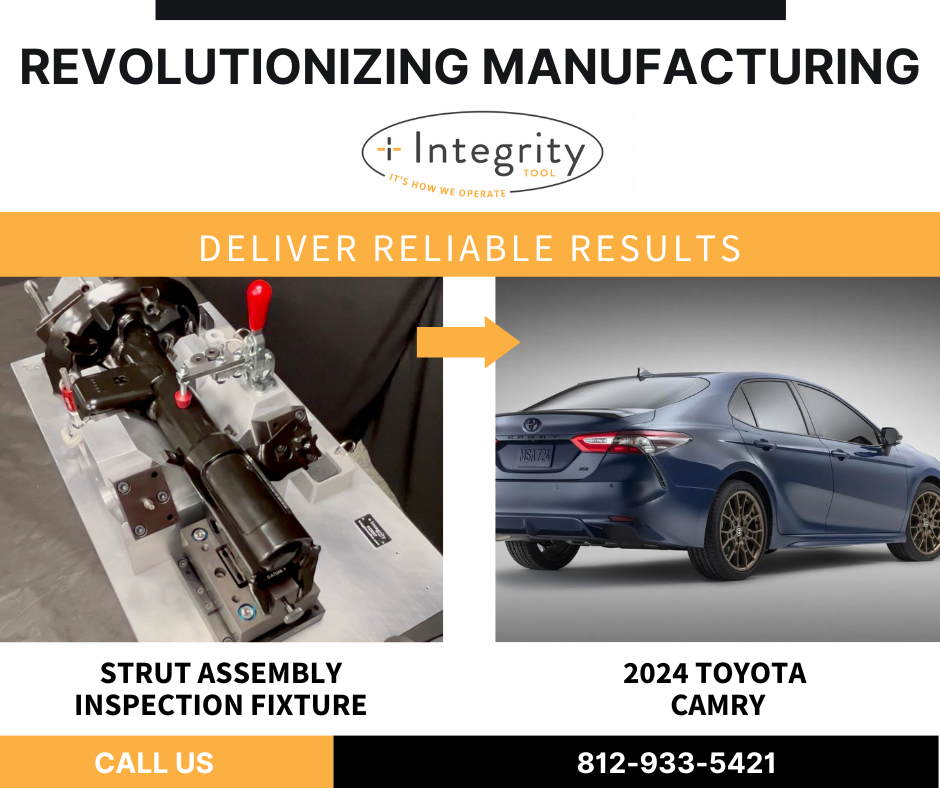

Attention all manufacturers and engineers! Are you tired of wasting time and money on multiple inspection fixtures? Look no further than the revolutionary Strut Assembly Inspection Fixture designed by Integrity Tool.

With its innovative floating datum block, this fixture eliminates the need for a second fixture, saving you valuable investment costs and manpower inspection time. Imagine the efficiency and cost savings you can achieve by consolidating your inspection processes into a single fixture. The days of juggling multiple fixtures are over!

The Strut Assembly Inspection Fixture goes above and beyond by incorporating a rotating plate. This ingenious feature allows for the spring seat to be inspected precisely according to the print, providing better correlation back to the CMM inspection process. Accuracy and consistency are paramount in manufacturing, and this fixture ensures that you meet the highest quality standards.

Our customer’s production line has been completely revolutionized by adopting this innovative fixture. They can now inspect welded assemblies during production, eliminating the need for costly rework and reducing the risk of defective products reaching the market. Furthermore, this versatile fixture can accommodate finished assemblies effortlessly, saving the significant expense of purchasing additional fixtures for various stages of the production process.

The Strut Assembly Inspection Fixture has proven its worth and effectiveness in supporting the production of the 2024 Toyota Camry. It has become an integral part of our customer’s manufacturing process, enabling them to meet strict quality requirements and deliver reliable products to their customers.

Integrity Tool is committed to providing solutions that make a real difference in your production line. We understand the challenges you face and have designed this fixture to solve three major problems for our customer: the floating datum block eliminates the need for a second fixture, saving investment costs and manpower inspection time. The rotating plate allows for precise inspection of the spring seat, ensuring better correlation with the CMM inspection process. And most importantly, this fixture supports inspecting both welded assemblies during production and finished assemblies, streamlining your operations and reducing costs.

Don’t let your production line fall behind the times. Contact Integrity Tool today and witness the remarkable results for yourself. Our experience and expertise are at your disposal, and we are dedicated to delivering solutions that uphold the highest standards of integrity. Trust us to help you optimize your manufacturing processes, enhance efficiency, and achieve unparalleled quality. Choose Integrity Tool because integrity is how we operate.